Low on-site manual labour requirements and low material cost because of use of CDW and other industrial waste.

Once produced at industrial scale, a material cost reduction of 10 €/m² compared to conventional ETICs is within reach. Whilst another 10 €/m² can be saved on scaffolding due to the prefabricated nature of the product.

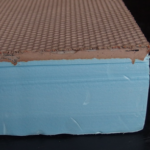

Better mechanical properties and better durability of the surface finishing compared to conventional rendering mortars in ETICs.

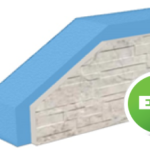

Wider variety of surface textures and finishes that can be applied compared to on site prepared ETICs, further reducing the total installed cost.

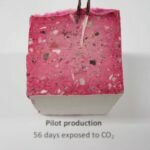

Environmentally friendly because of the use of geopolymers and high amounts of CDW and other industrial wastes, substantially reduced CO2 emissions and energy consump-tion during manufacturing.

Designed for easy dismantling/separation for better recycling of the panel at the end-of-life.